Magnetic Materials Treatments

Introduction

The influence of annealing on microstructure and magnetic properties of specialised magnetic materials is well established.

These materials are commonly identified by their trade names, for example, Carpenter steels. The following are generally well known for magnetic properties:

- Soft irons

- Swedish iron

- Cobalt alloy irons

- Silicon based irons

- Nickel alloy irons

- Very low carbon steels

Concerning the latter, it is possible to condition low carbon steels, with the right process, to give some benefit [but which would not be as effective].

Davis Scientific Treatments [DST] carries out Magnetic Annealing for these materials.

Annealing process

With this process, the work hardening of components, obtained through manufacturing, is substantially removed. The magnetic material is often recrystallised.

The treatment is preferentially carried out under an atmosphere which is a reducing agent, and sometimes hydrogen is used. However, the risk of flammability often makes use of an inert gas more desirable.

Although the improvements in magnetic properties are lessened slightly, DST uses Argon gas atmosphere. This has the advantage of production of parts without any treatment blemishes, and of course is safer.

To obtain the optimum blend of magnetic properties, for example, the coercivity, permeability, and remanence, accurate control of temperature, hold time, and cooling rate is required.

Any component which requires low coercivity, or high permeability, will benefit from annealing.

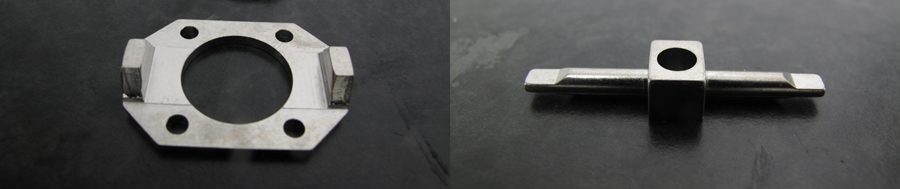

Typical applications are found in polepieces of servo valves, relay and solenoid parts [for example armatures and yokes], magnetic cores, and laminations [used in electric motors].

Davis Scientific Treatments [DST]

Here at DST we have extensive experience in the processes better known as Magnetic Annealing.

We are always very happy to advise and experiment, where necessary, to assist in finding the appropriate treatment for your application.